Welcome to the manufacturing ecosystem in Spain

In our last ecosystem article, the AFM- Advanced Manufacturing Technologies cluster takes us to the oldest industrial association in Spain still alive. Embark on this journey and learn more about our third greenSME cluster.

- What regions are covered by your cluster?

AFM is the oldest industrial association in Spain still alive. AFM represents the advanced manufacturing industry in Spain comprising more than 800 companies in the Manufacturing Ecosystem and value chain. We cover the machine tool builder including the components and tools and additive manufacturing companies to the parts manufacturers and consider the suppliers, R&D partners, start-ups and technology-based companies which can give a big added value to such ecosystem.

2. What is the representation of manufacturing in terms of all companies in the region?

Machining Data

According to the latest data we know, the number of companies involved in advanced manufacturing in Spain is around 6000 (mostly SMEs and micro SMEs).

- 3,120 companies, with an average turnover per company of 1 million euros and an average workforce of 12 employees. 12 employees.

Turnover per employee average: 83.000€.

- 1,860 companies, with an average turnover per company of 3 million euros and an average workforce of 25 employees. 25 employees.

Turnover per employee average: 120.000€.

- 1,020 companies, with an average turnover of 10 million euros and an average workforce of 65 employees. employees.

Turnover per employee average: 154.000€.

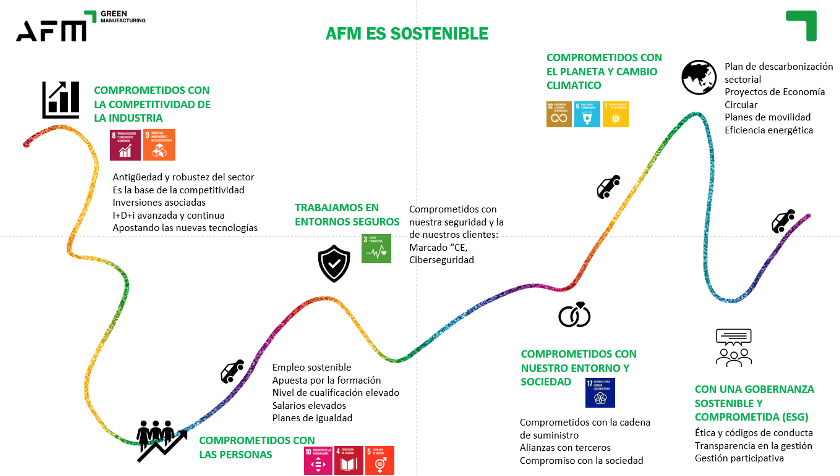

3. How has the manufacturing sector evolved in the three pillars of sustainability (environmental, social and economic) in your region over the past decade, and what are the key factors driving this change?

The sector has defined a sustainability strategy based on 6 pillars. These 6 pillars show a commitment to the competitiveness of the industry, to people, to safety in the workplace, to the social environment, to the governance of the companies themselves and to environmental sustainability. The following graph shows this commitment as well as the real indicators that support this strategy related to the sustainability of the sector:

This strategy is nothing new. The commitment to people, to competitiveness, to the environment, for example, is a commitment we have been working on for more than 20 years. We are a sector where employment is sustainable, where we are committed to training, where the level of qualification is very high and salaries are also high, where we are committed to R&D, where we take care that our workplace is a safe environment, where we are committed to the environment by promoting the value chain and local suppliers and where the circular economy and plans to reduce the environmental impact have been present for more than 10 years.

4. What challenges or obstacles in sustainability do manufacturers in our region face, and how have they adapted to overcome them?

The challenges we face in relation to sustainability are mainly based on the legislation and regulations that in recent years have been developed in a massive and, in our opinion, not very orderly manner.

In addition, major sectors that are important drivers of our economy are beginning to establish a series of requirements that are not homogeneous and that depend on the sector of activity or the size of the company or the particularities of that large driver company.

This means that small and medium-sized companies in the field of advanced manufacturing have to comply with a variety of requirements that are not very ordered and difficult to trace so that the activities that we have been carrying out in recent years can respond to these requirements.

On the other hand, SMEs are currently being asked to implement methodologies related to the measurement of their carbon footprint or environmental footprint, which are not very well developed and force them to carry out implementations that are not very agile and difficult to contrast and compare with other companies in the area or for other purposes. This is an added handicap faced by SMEs in the field of advanced manufacturing.

5. How does your cluster support the companies in becoming more sustainable? What services do you provide to companies?

The cluster tries to respond to those needs that are not sufficiently covered in the market. In recent years we have compiled the legislation and regulations that affect the companies in our cluster in terms of sustainability. We have also benchmarked and analysed different client sectors trying to understand their sustainability needs and requirements. We are launching pilot projects to help companies to have proven and agreed methodologies to assess their CO2 emissions. We are also trying to identify use cases or success stories so that companies can understand more clearly what good practices they may be implementing.

We facilitate the ecosystem so that companies have the necessary resources to respond to these sustainability requirements. We try to make the cluster a meeting point for entities that can collaborate to resolve these types of issues.

As for the activities we carry out, these are very varied: from holding conferences and seminars to launching collaborative R&D projects or setting up innovation projects in the field of sustainability with the participation of experts and interested companies. We are the meeting point and we have the resources and capabilities that companies may not have to help them move towards becoming more and more sustainable.